When ductwork isn't properly sealed, it can slash HVAC efficiency by around 30%, according to the Department of Energy's findings from last year. The system ends up working overtime just to keep things at the right temperature. Using insulation tape for air conditioning units helps create those tight seals where ducts connect and meet, fixing what many consider the single largest source of wasted energy in heating and cooling systems. Sealed ducts actually hold onto that conditioned air better, put less pressure on the compressor components, and stop those annoying temperature swings that make spaces feel uncomfortable.

Specialized sealing tape serves two main purposes at once: it creates a solid barrier against air movement and also resists moisture penetration. The sticky backing grabs onto ductwork surfaces really well, sealing those tiny gaps where air leaks out. These leaks can waste anywhere between 15 to 25 percent of energy in office buildings according to recent studies from ASHRAE. When properly applied, this tape keeps conditioned air inside where it belongs instead of letting it escape into areas like attics or crawl spaces. That helps maintain steady airflow throughout the building and stops the kind of condensation buildup that leads to mold problems down the road. Looking at what the industry data shows, HVAC systems sealed with proper tapes tend to perform better too. Buildings with these sealed systems often see their seasonal energy efficiency ratings jump by around 18 to 22 percent compared to older systems without proper sealing.

Proper application of insulating tape can cut down HVAC running time anywhere from 12 to 17 percent each year according to ACEEE research from 2023. That means real money savings for building owners over time. What's more, when HVAC systems don't have to work so hard all the time, they tend to last about three to five extra years before needing replacement. And guess what? The indoor air quality stays right where it should be according to EPA guidelines. Looking at things holistically, there are multiple advantages here: lower monthly utility costs, less frequent repair calls, and putting off expensive system replacements for longer periods. For facility managers concerned about both budget constraints and equipment longevity, getting this simple maintenance step right makes all the difference in the world.

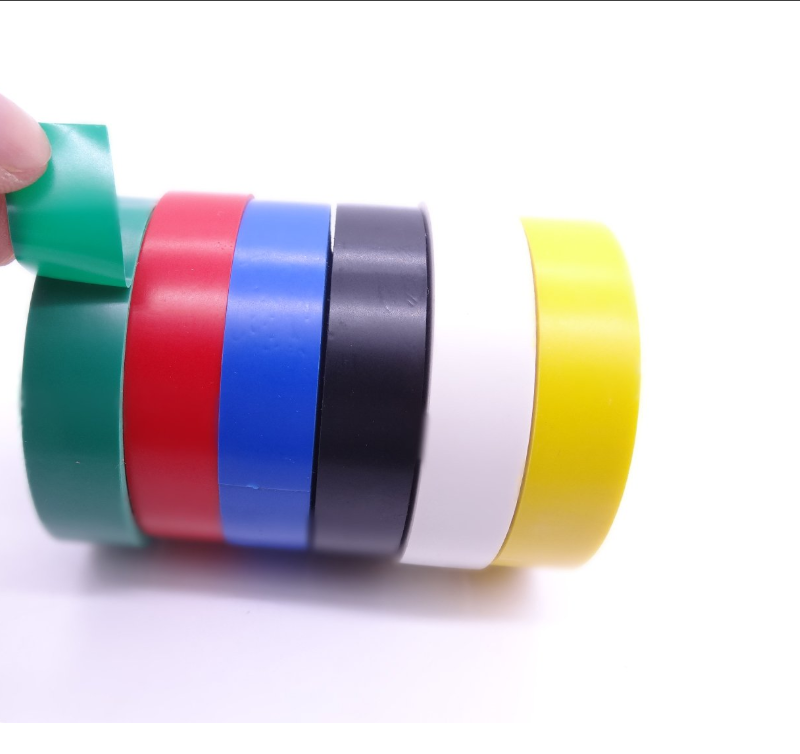

Aluminum foil tape is still widely used for sealing metal ductwork because it can handle pretty high temps around 300 degrees Fahrenheit and lasts quite a while. The tape does create those tight seals needed for high pressure HVAC systems, but there's a catch. When installed in colder areas or on those flexible duct sections, the rigid nature of the tape often causes it to lose grip over time. According to recent research from last year on HVAC efficiency, using foil tape cuts down duct leaks by about 35 percent when compared to regular tapes on the market. However, getting good results requires careful prep work beforehand since even small mistakes during installation can lead to peeling issues down the road.

Fiberglass tapes outperform in humid coastal regions, while butyl variants excel in vibration-heavy attics. For galvanized steel ducts in dry climates, foil tape delivers 15–20% better energy retention. Always verify adhesive compatibility—silicone-based tapes bond poorly to dusty or oil-contaminated surfaces.

Proper surface preparation ensures insulating air conditioning unit tape performs as intended, with studies showing that 96% of premature tape failures stem from inadequate cleaning practices. Follow these steps to create a durable, leak-free seal:

Begin by wiping duct surfaces with a lint-free cloth and isopropyl alcohol to remove dust, grease, and oxidation. Metal ducts require drying time of 15–30 minutes after cleaning, while fiberglass boards may need up to 2 hours due to their porous nature.

Avoid soap-based cleaners or abrasive pads that leave residues incompatible with tape adhesives. Test surface compatibility by applying a 2" tape sample—if edges lift within 24 hours, switch to a primer-rated adhesive or alternative tape type.

A stainless steel squeegee (6"–8" width) helps achieve 30–40 PSI pressure during application, exceeding the 25 PSI minimum recommended by HVAC sealing guides. Pair with utility knives featuring hook blades for precise cutting without tearing tape backings.

Apply tape using the "center-out" method:

This technique reduces bubble formation by 78% compared to linear application methods.

Small gaps where the insulation tape isn't properly sealed around air conditioning units can drop HVAC system efficiency anywhere between 15% to 20%, as shown in various energy assessments lately. Checking those duct joints regularly makes sense, particularly looking closely at bends and connection points where air tends to escape first. Before applying new tape, it's worth taking time to clear away any dust or dirt from the surface area. Press down firmly on the tape to get rid of those pesky wrinkles that just invite leaks later on. When dealing with corner sections, most technicians find cutting the tape into shorter pieces works better than trying to stretch it across awkward angles. This approach ensures proper stickiness throughout without risking damage to the material itself.

Tape tends to peel when surfaces aren't properly prepared or when dealing with really hot or cold conditions. When we see tape lifting at the edges, it's time to cut out those messed up sections and put new tape down with about two inches of overlap. Delamination is a big red flag that something's wrong with the adhesive compatibility. Always do a quick test run on a small section of ductwork before going all out. Want to save money on materials? Get those measurements spot on for duct circumference. And don't go nuts with tension while installing either. Too much stretch just leads to problems later on.

Create a maintenance schedule to check taped seams seasonally:

Proactive upkeep prevents energy loss and extends HVAC system lifespan by 3–5 years on average.

The Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA) recommends using UL 181B-listed tapes for ducts handling airflow above 2,000 CFM. Aligning with International Residential Code (IRC) Section M1601.6 ensures proper material ratings for fire resistance and vapor permeability. These standards reduce retrofit costs by 30% compared to non-compliant installations.

Insulating air conditioning unit tape helps create tight seals in HVAC systems, improving efficiency by reducing air leaks and maintaining steady airflow. This leads to energy savings, better indoor air quality, and longer system lifespan.

Consider climate, duct material, and specific usage demands. Different tapes excel in different conditions; for instance, fiberglass tapes work well in humid areas, while butyl is optimal for high-vibration locations.

Thoroughly clean and dry duct surfaces before application, avoid residues from soap-based cleaners, and test compatibility with a tape sample. Use tools like squeegees to apply consistent pressure.

Avoid improper surface preparation, incorrect tape type selection, and overstretching during installation. Regular inspections and maintenance help identify potential issues early.