In refrigeration systems, the condenser coils act as where most of the heat gets dumped out during operation. When the compressor pumps up the refrigerant into hot vapor form, it flows right into these coils. As this happens, the system loses heat to the surrounding environment both through direct contact and air movement around the coils. The design of modern condensers includes lots of surface area thanks to those little metal fins we often see sticking out. Materials such as copper or aluminum are commonly used because they conduct heat really well. According to industry standards, about two thirds of all heat picked up by the refrigerant actually leaves here. Commercial units typically have bigger fans blowing across the coils too, which helps things cool down faster when there's more work being done. Getting this part right means the refrigerant comes out at just the right temperature so it can turn back into liquid form properly.

When refrigerant gets cooler inside the condenser unit, it changes state from vapor back into liquid form. What we call subcooling happens when this liquid is cooled even further past what's called the saturation temperature point. This extra cooling step prevents any flash gas formation right before reaching the expansion valve. Good subcooling practices can boost overall system performance somewhere around 12 to maybe even 15 percent because it keeps refrigerant flowing consistently through the system according to HVAC Tech Institute research last year. The coils in these systems create turbulence that helps spread out heat evenly across surfaces. After being completely turned into liquid and properly subcooled, the refrigerant heads off towards the evaporator section. Newer models with microchannel technology manage to get subcooled much quicker than older designs did, which means modern fridges generally consume less power while doing the same job.

The way heat moves through condenser coils depends mainly on two processes: conduction and convection. When the refrigerant gets hot inside the coil, it conducts heat right through those metal walls. At the same time, the surrounding air takes care of convective cooling, basically stealing away the excess warmth. Some systems rely on natural air movement, but most modern setups have fans blowing air across the coils, which works much better for keeping things cool. Studies suggest that expanding the condenser surface area by around 30 percent might boost heat loss efficiency somewhere between 18-25 percent, though results vary depending on specific conditions. That's why many manufacturers design their coils with long, winding copper tubes combined with lots of aluminum fins sticking out everywhere. These fins dramatically increase how much contact there is with cooling air, ultimately making the whole system work harder at shedding heat.

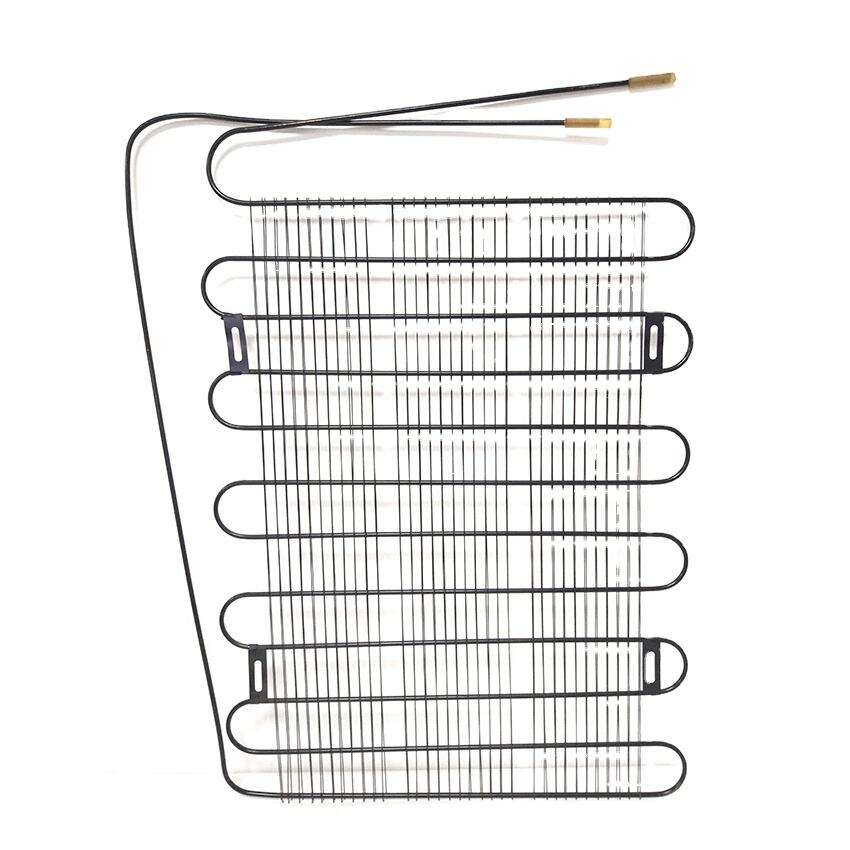

The shape and design of condensers really matters when it comes to how well they handle heat. Copper is great stuff for this because it conducts heat so efficiently at around 401 W/mK. That means heat moves through it quickly. Aluminum fins attached to these copper components help too since they create more surface area which helps cool things down better through convection. We're seeing more microchannel designs lately, and these can cut down on refrigerant needs by somewhere between 25% and 40% compared to older tube and fin models. When manufacturers stagger those fin patterns, they actually create more turbulence in the air flow, which boosts heat rejection rates by about 12% to 18% in systems where air is forced through them. Research from the Coil Material Efficiency Report backs this up. All these improvements mean smaller home units can still perform well even though they have limited space to work with.

A typical coil fridge condenser system has three main parts working together to get rid of heat properly. The coils themselves are usually shaped like snakes and made from either copper or aluminum because these materials allow for good contact area when transferring heat away from the system. There are also inlet and outlet pipes connected to control how fast the refrigerant moves through the system. This helps maintain just the right pressure difference between where the compressor sends the refrigerant and where it picks it up again at the evaporator. Some recent research from ASHRAE back in 2023 showed that getting this refrigerant flow right can cut down on energy usage by around 12 percent in regular fridge models. That's quite a significant saving over time for households and businesses alike.

Most homes still rely on copper tubing for their HVAC needs, holding around three quarters of the market thanks to how well it conducts heat. Aluminum is starting to make waves in bigger commercial setups though, grabbing about 22% of that space because it's so much lighter to handle during installation. When setting up these systems, technicians usually pair inlet pipes with compressor outputs ranging from 1/4 inch to 3/8 inch diameter to keep things flowing smoothly without creating bottlenecks. The way outlets are configured helps cool down the refrigerant properly before it hits the expansion valve. Getting this right makes all the difference for maintaining stable operation and ensuring proper phase changes happen when they should.

Axial fans powered by brushless DC motors can move anywhere from 150 to 300 cubic feet of air per minute across coils. That's actually about 40 percent better than those old shaded-pole motor designs we used back in 2018. The blades on these fans are set at angles ranging between roughly 22 degrees and 35 degrees which helps transfer heat more efficiently while still keeping the noise level below 45 decibels in most home appliances today. Studies looking at commercial refrigeration systems found something interesting too. When manufacturers switched to variable speed fans instead of fixed speed ones, they saw their yearly energy consumption drop by around 18%. These smart fans simply adjust how much air moves through based on what the system actually needs at any given moment.

About 92 percent of commercial HVAC setups rely on forced airflow systems because they need to keep that temperature difference (ΔT) above 15 degrees Fahrenheit. Meanwhile, around a third of smaller homes still use natural convection methods since they're simpler and cheaper to install. The newer hybrid models mix these two techniques together, turning on extra fans only when temps inside go past certain points. According to the latest Energy Star numbers from 2023, this kind of smart approach cuts down how often compressors cycle on and off by roughly 23%. Fewer cycles mean parts last longer and overall system performance gets better over time.

When dust builds up on those condenser coils, it cuts down heat transfer efficiency somewhere around 30%. That means compressors have to work extra hard, running anywhere from 12 to 18 percent longer just to keep things at the right temperature. The result? Residential units end up consuming between 15 and 25 percent more energy than they should. For businesses where equipment runs constantly throughout the day, these numbers get even worse. Those clogged fins basically become little heat traps, letting temperatures climb past what's safe for the system. Most maintenance manuals for commercial refrigeration systems will tell operators that regular cleaning makes all the difference. After a good cleanout, most systems bounce back to normal operation pretty quickly, usually within two days or so. It's worth the effort because keeping those coils clear saves money in the long run and prevents premature equipment failure.

Improper refrigerant levels lead to distinct operational issues:

Field data indicates that 42% of compressor failures stem from prolonged refrigerant imbalances. Overcharging often results in liquid slugging, damaging valve plates in 93% of such cases. Undercharging accelerates oil degradation by three times compared to correctly charged systems, reducing lubrication effectiveness and shortening compressor lifespan.

The latest microchannel condenser technology beats old school tube and fin systems when it comes to heat rejection efficiency, typically around 22% better performance. What makes these new models so effective? Well, they feature refrigerant pathways that are about 40% narrower than before. Plus, they're built with aluminum which conducts heat three times faster than those steel alternatives. And let's not forget the clever airflow guides that actually save on fan power consumption somewhere around 18%. All these upgrades mean better system performance overall. Maintenance expenses drop too, somewhere between sixty to a hundred and forty dollars each year per unit installed. For plant managers trying to comply with those tough new 2024 Department of Energy regulations, this kind of efficiency makes all the difference in staying competitive without breaking the bank.