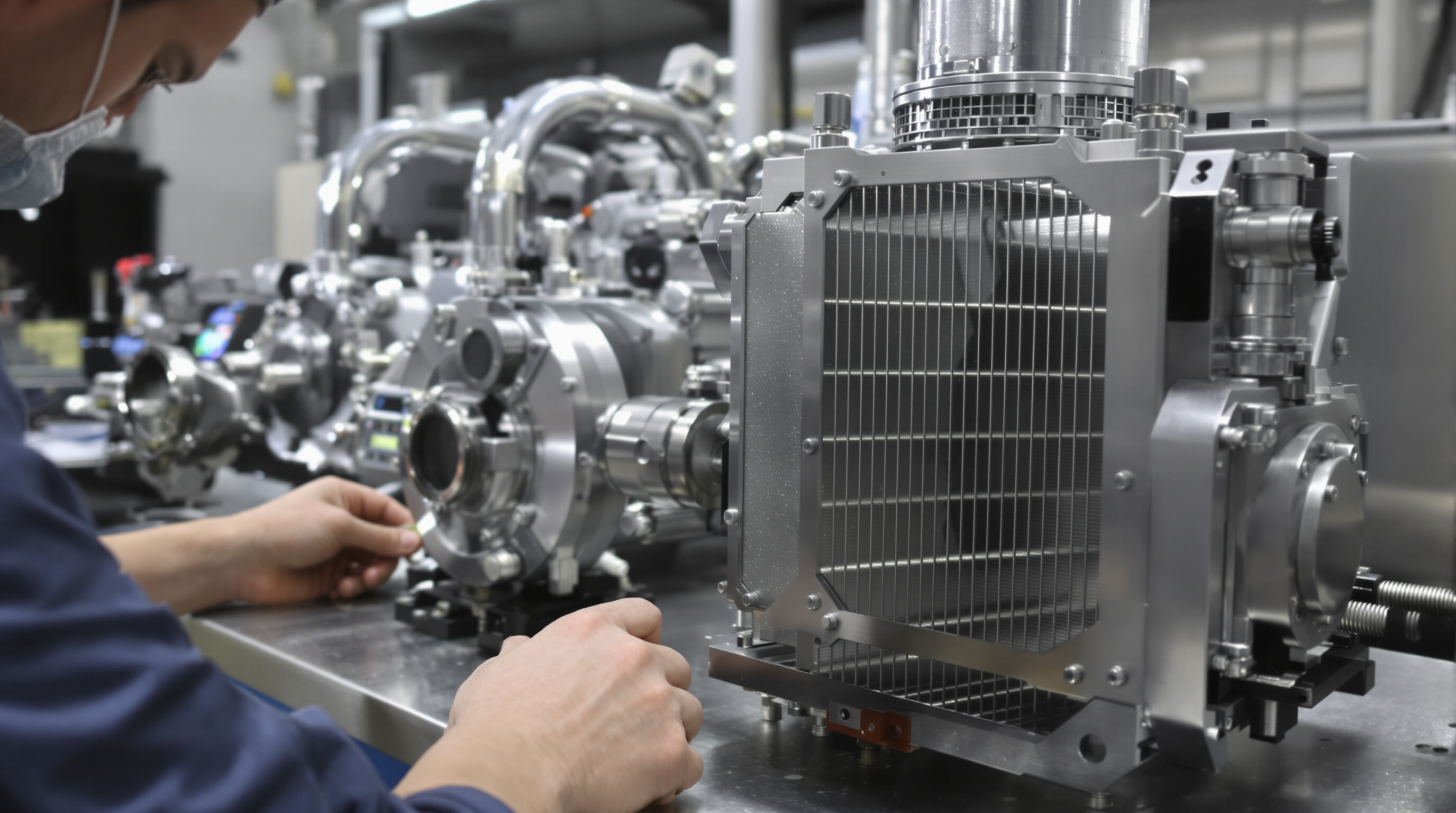

The growing need for energy has pushed companies to rethink how they make parts for refrigeration and air conditioning systems, especially when it comes to cutting down on wasted resources. Heat exchangers these days often feature microchannel technology, which boosts heat transfer rates maybe around 30% or so according to some tests, plus it requires less refrigerant overall. For compressor scrolls, digital machining techniques allow manufacturers to create components with much finer details, something that reduces both friction points and unwanted energy loss during operation. When looking at whole systems, these small but important upgrades matter everywhere from valves to sensors right across all those surfaces where heat actually moves between materials. Industry experts point out that even minor changes in component design can lead to noticeable differences in how efficiently cooling systems perform over time.

Compressors powered by inverters along with VRF (Variable Refrigerant Flow) systems manage to slash energy usage because they adjust cooling based on what's actually needed at any given moment. Traditional systems just turn themselves on full blast then shut down completely, but inverter tech keeps things running smoothly even when there's not full demand. This approach cuts power consumption somewhere between 20% and 40% depending on conditions. When it gets really hot or cold outside, advanced vapor injection techniques help maintain system performance. The valves inside these modern systems work electronically to control how much refrigerant flows through based on both temperature readings and whether people are actually present in the space. Manufacturers continue improving these technologies too, incorporating sensors that track fluid movement with accuracy around plus or minus 2%. These small but important improvements mean buildings stay comfortable without wasting unnecessary electricity.

The U.S. Department of Energy reports that HVAC systems eat up around 40% of all energy used in commercial buildings, making them a prime target for efficiency improvements. We've seen some interesting developments lately at the component level. For instance, those fancy diamond-like carbon coatings applied to valve stems cut down on friction losses by about 37%. Meanwhile, compressors are getting a boost from oils infused with nanoparticles that really stick to metal surfaces. Another neat trick comes in the form of temperature responsive polymer seals that actually adjust themselves when going through those hot and cold cycles, stopping those pesky refrigerant leaks that can drain anywhere between $10k to $15k each year from facility budgets. What makes these upgrades so appealing is that they don't require replacing entire systems just parts here and there, leading to tangible reductions in energy consumption over time.

Regulations around the world including SEER2 and EU's F-Gas directives have pushed companies to rethink old parts like condenser coils and expansion valves in their systems. The industry now faces efficiency targets that are roughly 10 to maybe even 15 percent higher than before, all while switching over to these newer refrigerants that have lower global warming potential but also carry some flammability risks classified as A2L. According to findings from the recent 2024 European Commercial Refrigeration Market Report, manufacturers are rushing to incorporate materials that resist corrosion and install those sealed electrical connections throughout their products. These changes aren't just about meeting paper requirements either they actually help keep equipment safer and bring products into line with what different regions demand for proper operation.

The combination of IoT technology and artificial intelligence is changing how refrigeration and air conditioning systems work, mainly through real time monitoring and smart control features. These systems now have built in sensors that send information back to central hubs, which lets them tweak things like compressor speeds and refrigerant flow rates automatically. Smart software looks at all sorts of factors including pressure readings, temperature changes, and historical operation patterns to spot potential problems long before they actually happen. Some studies suggest this predictive maintenance can cut down on repair bills by around 40%, though results may vary depending on system age and usage conditions. Beyond saving money on repairs, these intelligent systems also help reduce overall energy consumption while still keeping temperatures exactly where they need to be in everything from grocery store freezers to hospital operating rooms.

Smart thermostats look at past occupancy patterns to tweak cooling schedules automatically, which can slash energy consumption for commercial HVAC systems around 30 percent in many cases. When it comes to maintenance, wireless vibration sensors hooked up to IoT systems pick up on early warning signs that compressors might be out of balance, sending out immediate alerts so technicians can fix problems before they escalate. For big operations such as data centers or cold storage warehouses where every hour counts, these predictive features help keep things running smoothly while also hitting those green targets. The result? Less time spent waiting for repairs and significantly reduced energy bills across the board.

Integrating smart components reduces mechanical stress, extending equipment life. Continuous optimization prevents overheating in compressors and valves, lowering wear-related degradation by nearly 25% compared to conventional systems. Seamless interoperability and regular software updates reinforce long-term reliability, supporting sustainable building operations and compliance with evolving industry standards.

As countries around the world move away from high-GWP refrigerants like R-410A, we're seeing major shifts happening across the refrigeration and air conditioning industry. Parts manufacturers report that getting compatible compressors and valves costs anywhere between 15% to 25% more according to market research from Future Market Insights in 2024. But this price bump has actually pushed companies to get creative with their materials and designs. Heat exchangers now commonly feature corrosion resistant alloys that last longer, while equipment makers have started incorporating modular designs that make retrofitting old systems much easier. The industry is also turning toward hermetic systems because they seal better and reduce leaks, which helps meet environmental regulations while saving money over time as maintenance needs drop significantly.

About 38 percent of new refrigeration systems now use natural refrigerants such as CO2 (R744) and hydrocarbons (R290), though these alternatives come with their own set of problems when it comes to installation. The CO2 systems need parts that can handle pressure levels around ten times what standard systems experience, which is quite a challenge for many facilities. Hydrocarbon refrigerants present different issues altogether since they're flammable materials that must be kept within specific zones according to safety regulations. When trying to retrofit existing equipment with these newer options, there's typically around a 32% drop in efficiency because older systems weren't built to work with the right kinds of lubricants. To get past these hurdles, manufacturers have started incorporating stronger valves, better sealing mechanisms, and advanced sensor technology throughout the system design process. These upgrades help ensure compliance with the latest standards outlined in ASHRAE 34-2022, even though meeting those specs sometimes requires significant modifications to conventional equipment layouts.

The new generation of A2L refrigerants needs a tricky balance between how well they work, their potential to catch fire, and what happens if someone is exposed to them. Manufacturers have started putting things like infrared leak detectors right into the systems now, plus flame arrestors that handle those minor flammability issues. The compressors themselves are getting pretty good these days too. Some models reach almost 95% thermal efficiency which is impressive. But don't forget about material choices either. Copper and aluminum combinations are becoming popular because they stop that annoying galvanic corrosion problem while keeping greenhouse gas potential under 150. This approach actually gives companies a realistic way forward if they want to run their operations without harming the environment so much.

The latest HVAC systems are starting to incorporate more eco-friendly materials these days. Manufacturers have begun using bio-based polyurethane foams alongside recycled aluminum for many components, with this green approach making up about half of all insulation work and heat exchanger builds. When it comes to production methods, additive manufacturing techniques cut down on waste significantly - somewhere around 58% according to industry reports. What's really interesting is how companies design products for their end-of-life stage too. These designs make it easier to take apart old units, which means manufacturers can recover roughly 90% of materials for reuse. There's also growing support from groups like the HVAC Sustainability Partnership that push for circular economy approaches. Basically, they want old HVAC units to become raw materials for new ones rather than ending up in landfills. This kind of thinking helps reduce environmental damage throughout the entire product life cycle, from manufacturing right through to disposal.

The type of cooling technology used determines what kind of refrigeration parts are needed. For vapor compression systems, we're talking about high efficiency compressors paired with condensers that won't corrode when working with refrigerants such as R-32. When it comes to evaporative cooling methods, things get interesting because they depend heavily on special materials that can hold water and distribute it precisely to manage humidity levels effectively. Then there's absorption cooling which presents another challenge altogether requiring heat exchangers built to last through all sorts of temperature changes while dealing with those tricky lithium bromide solutions. Recent studies published in the latest edition of Materials Science Review have actually demonstrated through computational fluid dynamics simulations exactly how these different needs influence choices about materials and overall system design.

Thanks to additive manufacturing techniques, we now see microchannel heat exchangers that boast around 22 percent better thermal conductivity. This advancement means systems require roughly 30% less refrigerant overall. Moving on to compressors, variable speed units equipped with magnetic bearings are making waves too. These newer models slash energy losses by about 18% when compared against older conventional designs. For those working in demanding conditions, graphene based coatings applied to compressor rotors make all the difference. They significantly boost component lifespan under pressure while still working well with modern low global warming potential refrigerants. The result? Equipment that performs better day after day without compromising environmental standards.

Combining thermoelectric modules with traditional vapor compression tech is creating a real market push for components that can handle multiple functions at once, such as those dual-mode expansion valves we've been seeing more of lately. According to last year's Thermal Management Industry Snapshot, manufacturers are now embedding microfluidic cooling arrays right into condenser plates themselves. This allows much finer control over temperatures in those dense electronic setups where heat management matters most. But all these innovations come with their own challenges. The industry needs fresh manufacturing specs and completely different testing methods if they want these hybrid systems to work reliably under all sorts of real world conditions beyond standard lab environments.

More people moving into cities plus hotter weather conditions are creating huge new demand for air conditioning systems across many developing countries. Market forecasts suggest the HVAC business could expand around $90.5 billion by 2029 growing at roughly 7% per year, while most of the new equipment will actually go into installation in emerging markets. Think about data centers too they currently consume about 3 percent of all electricity worldwide and need special cooling parts because they generate so much heat in one place. Companies are now making compressors tailored for different regions along with smart temperature sensors that work well without wasting power. Looking at recent trends in construction activity, we see that product development cycles for cooling components have sped up significantly since mid-2023 as businesses try to keep up with what customers want.

The chaos following the pandemic has pushed many industries toward creating regional manufacturing centers while companies consolidate operations strategically. The big five players in this space have really expanded their dominance, grabbing nearly half (52%) of the market since 2019 by snapping up smaller competitors. Most businesses today maintain spare parts stockpiles no more than 500 miles away from where they install them, which has slashed waiting periods down from around three months to just one month. Advanced software tools now warn about potential supply issues roughly six weeks ahead of time, giving managers breathing room to react. And then there's the whole 3D printing revolution happening at local levels too these days. These small scale fabrication shops can churn out essential components almost overnight when traditional shipping routes get blocked, something that became painfully obvious during those long lockdown periods.

More manufacturers these days are switching to circular production methods that follow ISO 14001 guidelines, keeping tabs on carbon footprints from raw materials all the way through to disposal. The U.S. government's tax breaks have pushed companies to spend around 23 percent more on research for things like biodegradable alternatives and second life programs for old products. Looking at recent industry reports, businesses that implemented closed loop recycling systems saw their production emissions drop by about 31% over just two years from 2022 to 2024. These numbers really highlight why going green isn't just good for the planet but also makes financial sense in the long run for most manufacturers trying to stay competitive while reducing their environmental impact.

Energy efficiency is the main driver as it reduces wasted resources and enhances overall system performance.

They adjust cooling based on actual needs, cutting power consumption by 20-40%.

Challenges include handling pressure levels, flammability concerns, and compatibility with older systems.

They reduce mechanical stress and optimize system operations, lowering wear and improving energy efficiency.